Recording studios often have treated rooms, which utilize physical Absorber, Reflectors and Dispersion units to treat the room for better recording and mixing

Author Archives: ModGuitar Senior Editor

Working With 4-Track Tape Recorders

The advantages of tape are analogue saturation and compression, and vintage linear workflow

Ibanez S270 Dragon Custom

I was inspired by Jimmy Page’s Telecaster

Sonnox Listen Hub for OSX

Listen Hub doesn’t make a lot of wild claims, but what it does do is get you focused on your listening experience

Disco wasn’t so bad

The musicians took a back seat though only to reclaim the line light with Punk and Glam rock just around the corner.

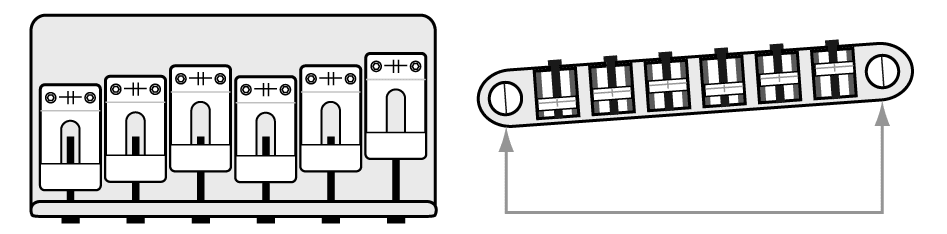

Locking Tremolo Set-up Guide

Locking tremolos provide great tuning stability. They can be a source of frustration. This tutorial shows you how to set-up a locking tremolo. Traditional tremolos still have their place, but locking tremolos reign supreme for staying in tune. The only set-back is getting the system set-up in the first place, particularly in full floating mode. …

The Ultimate Guitar Set-Up Guide

Buying A Guitar: Budget & Recommendations

So, you’re looking to buy your first guitar? There are so many models, options, and features to compare, I thought it would be beneficial to outline some of the features to look for, some of my personal picks, and market trends. Depending on your goals; wether you intend to dive in and learn yourself, take …

Continue reading “Buying A Guitar: Budget & Recommendations”

TASCAM 2X2 USB Audio Interface.

First Impressions Manual in box, no discs, Ableton Live Light 9 code card (requires Ableton account to add serial number to account before activation can go through), Sonar brochure (not used, I’m on Mac). It’s a strudy medium sized desktop unit, doesn’t seem prone to sliding around and has some heft to it. The knobs …

TASCAM TC-S1 Solar Tuner Quick Review

Here’s a YouTube video review, TASCAM TC-S1 Solar Tuner. A great, lightweight yet sturdy, and compact tuner that charges an internal battery by solar power. Small enough to fit anywhere. Features 4 tuning modes: Animated Strobe, Meter, Needle, and a Fine Tuning mode as well as calibration from A437-A445. A fast internal processor coupled with …

Logic ProX New Guitar Tones.

LogocProX has several updated and new guitar effects and amp simulations. The best part of the latest version of Apple’s proffesional caliber recording software – the learning curve has been eased. Enhancements to the user interface have given a fresh look and feel to legacy visual style, which had origins in the Emagic version of …

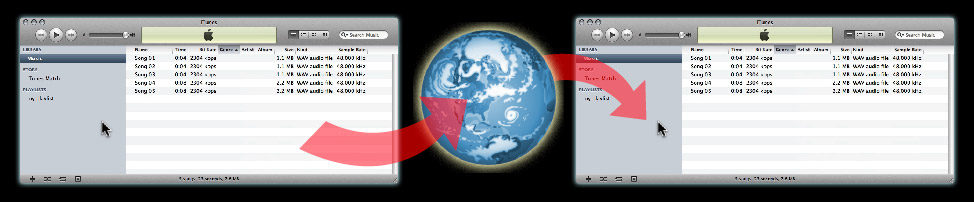

Logic Pro X and Reason – How to Rewire

Logic Pro x, a 64 bit app requiring OSX 10.8.4 introduces new routing options for rewire apps. Reason 6.0 is required for 64bit computability. 1. Launch Logic Pro X. 2. Launch Reason 2a. Reason should launch into 64 bit (rewire 1.8.1) mode – as indicated in the master routing section. *graphic* 3. Set-up your Reason …

Used Guitar Buying Guide

Prices of new guitars keep going up. A used guitar can be a great value. Use this ten point guide to evaluate your used guitar or bass purchase before buying.

Fender Standard Telecaster

The Fender Standard telecaster is a key guitar designs that has inspired generations of guitarists to pick up thine axe and play Read The Review Here

Apple Garageband Virtual Guitar

iTunes Playlists, Export and Import.

SP Sound Percussion Double Bass Drum Pedal Set-Up And Review

Just in for review. Sp Sound Percussion Double Bass Drum pedal. A great deal from Musician’s Friend as one of their “Stupid Deals Of The Day”. Watch as I unpack it, set it up, and then give a quick playing example.

Fender Strat Plus Bi-flex Truss Rod Fix and Pick-up Swap.

Locking Tuner Upgrades: Pros and Cons

HowTo – Projects, Tutorials, And More

EBO Bass To Guitar Conversion Follow along as we convert a beat up non-collectable Gibson EBO bass from the late ’70s and convert it to a SG guitar. It was a big project that went really well as the clips and photos show. Midi Guitar Custom Build We wanted to get the best of both …