Recording studios often have treated rooms, which utilize physical Absorber, Reflectors and Dispersion units to treat the room for better recording and mixing

Category Archives: HowTo

The Ultimate Guitar Set-Up Guide

Buying A Guitar: Budget & Recommendations

So, you’re looking to buy your first guitar? There are so many models, options, and features to compare, I thought it would be beneficial to outline some of the features to look for, some of my personal picks, and market trends. Depending on your goals; wether you intend to dive in and learn yourself, take …

Continue reading “Buying A Guitar: Budget & Recommendations”

Logic Pro X and Reason – How to Rewire

Logic Pro x, a 64 bit app requiring OSX 10.8.4 introduces new routing options for rewire apps. Reason 6.0 is required for 64bit computability. 1. Launch Logic Pro X. 2. Launch Reason 2a. Reason should launch into 64 bit (rewire 1.8.1) mode – as indicated in the master routing section. *graphic* 3. Set-up your Reason …

Used Guitar Buying Guide

Prices of new guitars keep going up. A used guitar can be a great value. Use this ten point guide to evaluate your used guitar or bass purchase before buying.

Apple Garageband Virtual Guitar

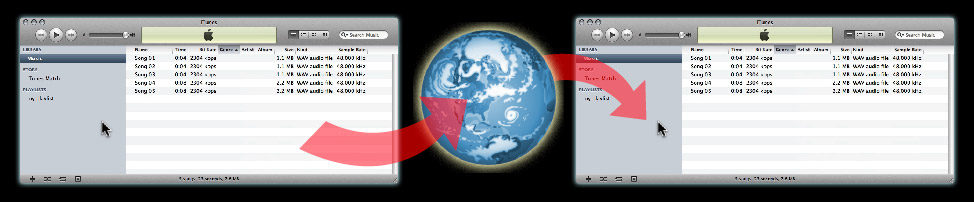

iTunes Playlists, Export and Import.

Fender Strat Plus Bi-flex Truss Rod Fix and Pick-up Swap.

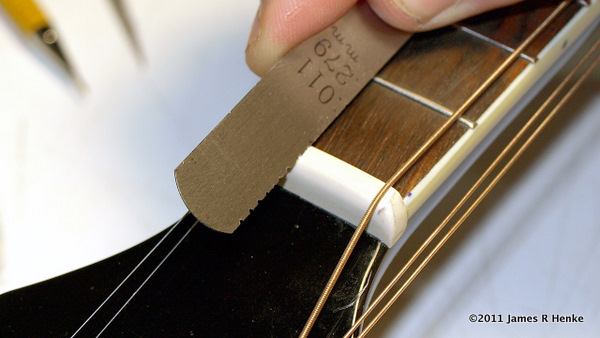

Mandolin Fret Dress and New Nut

I acquired this Fullerton “A” style mandolin a few years ago when one of the big retailers was closing out the brand. It’s a nice instrument overall, well constructed and for the price was a great way to learn some mandolin. What I’ve found lacking was the fret-work. So here we go, getting down to brass-tacks and doing a pretty thorough fret dress.

Mod The Ramen!

Tune Your 4 String Bass Standard Tuning EADG

Tune Your Mandolin

Simple play this video and match your mandolins pitch, string-by-string and you’ll be tuned up in just a few minutes. The videos can be played full screen, so you can follow along from across the room. Turn it up and get it tune!

Mandolin 4 sets of dual strings tuned in unison. The strings are tuned from the 4th (thickest) string to the 1st G, D, A, E.

Tune Your Guitar

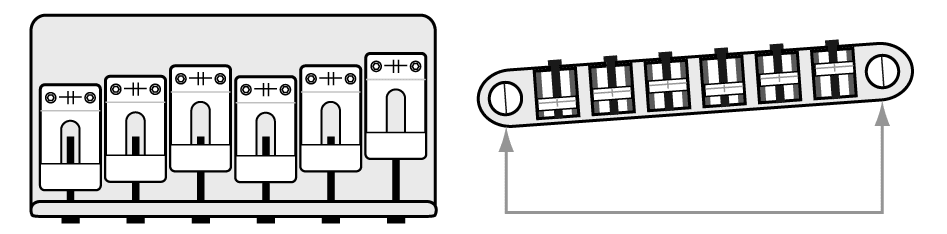

Basic Tool Kit

Every mod, repair, set-up, or build project begins with the use of tools. Some specialized some common. Here we run down the basic Luthier’s tool chest as well as additional tools required to do mods, set-ups, wiring, building and making guitars. Doing your own set-ups and seasonal adjustments requires a basic set of tools.

Modder's Tool Kit Essentials

Changing Strings: String Winding/String Snapping

String winding is the kind of thing that, done right, can have a real impact on how your guitar plays, and more importantly – stays in tune.

Follow along and learn how to change your strings, wind them on the posts and then snap them to remove slack for the best tuning stability and long string life.

Tuning The Guitar

Quick Nut Fix

If you’ve ever worked on your nut, you know how easy it is to go a little too far in the search of comfortable low action ending up with some string buzz. The nut can waer down in time, or you may notice a pinging sound when tuning up or playing. Fortunately, there is a quick fix that can get your guitar up and running again in just a few hours

ModGuitar Custom Midi Guitar Build

Gibson 'EBO' Bass To 'SG' Guitar Conversion

Hidden away in the workshop we found a semi-vintage Gibson EBO bass. The headstock couldn’t seem to keep from snapping off. It had been repaired a few times already and was missing some parts and crucial components like the pick-up. It also just happened to not play or sound very good. Vintage SGs fetch high prices, and this SG body was still intact…so The SG BASS-GUITAR MOD is born.